Lithium battery production low current battery pack

Custom Lithium Battery Pack Manufacturing: A Technical End-to

Our methodology ensures every custom lithium-ion battery pack – from ultra-low-temperature 18650 configurations to high-voltage LiFePO4 arrays – delivers uncompromised

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Ultium Cells to upgrade Tennessee plant for low-cost EV battery

SPRING HILL, Tenn. - Ultium Cells LLC, a joint venture between General Motors and LG Energy Solution, will upgrade its Spring Hill, Tennessee battery cell manufacturing

10s-16s Battery Pack Reference Design With Accurate Cell

Description This reference design is a low standby and ship-mode current consumption and high cell voltage accuracy 10s–16s Lithium-ion (Li-ion), LiFePO4 battery pack design. It monitors

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

All essential components of a lithium ion battery pack are addressed to support engineers developing both simple portable devices and complex motive applications. The

Prices of Lithium Battery Packs and Cells: Updated Data

The decline in prices is attributed to several factors, including excess battery cell production capacity, economies of scale, low metal and component prices, and the adoption of

Advancing lithium-ion battery manufacturing: novel technologies

Lithium-ion batteries (LIBs) have attracted significant attention due to their considerable capacity for delivering effective energy storage. As LIBs are the predominant

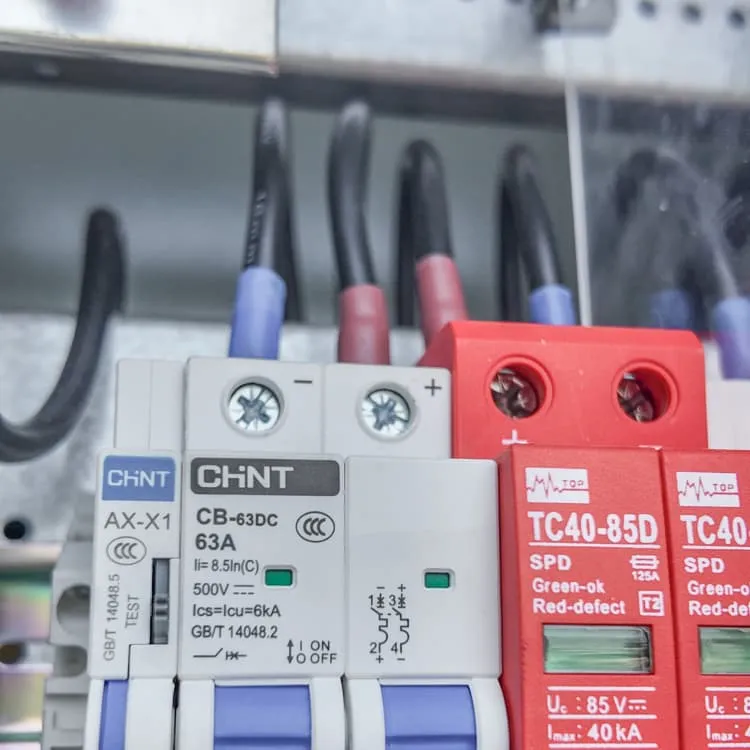

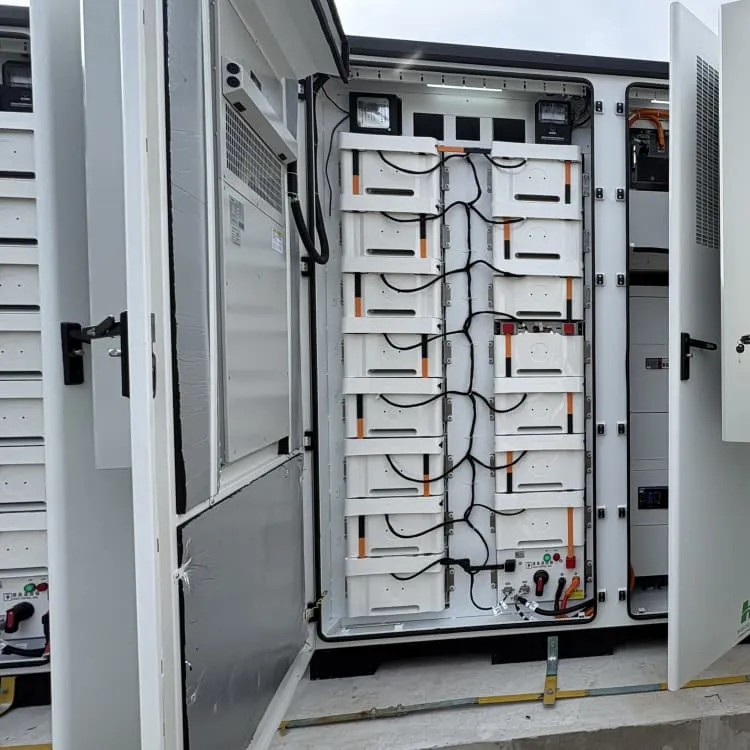

Lithium Battery PACK Production Line Processes and Equipment

Here is an overview of the Lithium Battery PACK line: Cell Types. Cells are the basic units that make up the battery pack, mainly divided into: Prismatic Cells: With high energy density and

Cost modeling for the GWh-scale production of modern lithium-ion

Abstract Battery production cost models are critical for evaluating the cost competitiveness of different cell geometries, chemistries, and production processes. To address this need, we

The Ultimate Guide to 18650 Battery Packs: Design, Benefits, and

The Ultimate Guide to 18650 Battery Packs: Design, Benefits, and Charging Best Practices Introduction In the rapidly evolving landscape of portable energy storage, the 18650 battery

More industry information

- Hungarian outdoor energy storage cabinet factory price

- Mauritius energy storage battery container manufacturer

- Melbourne Battery Energy Storage

- Gravity Energy Storage Project Costs

- 5kw home solar power system

- South Korea s communication base station power supply infrastructure

- Guatemala imports photovoltaic cell modules

- What is a mobile energy storage charging pile

- Lithium battery pack 48v large capacity

- Solar system home costs in ASEAN

- Dimensions and specifications of various solar panels

- St Kitts and Nevis lithium battery and inverter

- Huawei Angola energy storage lithium battery brand

- How do 5G base stations charge

- Solar photovoltaic power generation in Lebanon

- Mexico Electricity Supply Bureau Energy Storage Power Station

- Photovoltaic panels and battery usage scenarios

- Cook Islands Telecommunications Base Station Hybrid Energy Location

- Energy storage battery capacity of solar charging station

- The fastest outdoor charging power bank

- Future ESS6 price

- Energy storage battery new energy manufacturers

- Fast charging and discharging energy storage battery

- Paraguay lithium battery outdoor energy storage project

- Base station lithium battery energy storage 20kw inverter price

- Outdoor Power Supply Peripherals

- Energy Storage Plus Virtual Grid