Motor energy storage device

Designing high-speed motors for energy storage and more

Mechanical energy storage can be added to many types of systems that use heat, water or air with compressors, turbines, and other machinery, providing an alternative to battery storage,

Research and analysis on brake energy recovery of pure

Research indicates that electrochemical energy storage represents a superior approach for recycling energy due to its ability to enhance energy recovery efficiency through algorithmic

Energy storage technology and its impact in electric vehicle:

The desirable characteristics of an energy storage system (ESS) to fulfill the energy requirement in electric vehicles (EVs) are high specific energy, significant storage capacity,

Motor Starting Energy Storage Devices: Powering Industries with

That''s where motor starting energy storage devices become the espresso shot your machinery needs. Primarily used in manufacturing plants, mining operations, and power generation

Modeling and simulation of photovoltaic powered battery

Energy storage is crucial for the powertrain of electric vehicles (EVs). Battery is a key energy storage device for EVs. However, higher cost and limited lifespan of batteries are

How does the energy storage motor automatically store energy?

As the motor operates, excess energy is directed toward the flywheel, which begins to spin faster, thus retaining energy in the form of mechanical energy. When more energy is

NoMIS Power Launches First 3.3 kV SiC MOSFET, Setting New

6 days ago· The device is aimed at a broad spectrum of applications, including battery energy storage systems (BESS), renewable energy inverters, electrified transportation platforms, and

Energy recovery for hybrid hydraulic excavators: flywheel-based

The ERS is composed of an energy storage device, an energy converter, and some auxiliary elements. At present, hybrid systems available for HEs can be divided into three

Elastic energy storage technology using spiral spring devices and

Elastic energy storage using spiral spring can realize the balance between energy supply and demand in some applications. Continuous input–spontaneous output working style

Micromotors for Energy Storage | Efficient Storage Solutions

Elevate your energy storage solutions with our cutting-edge generators, engineered to harness and store mechanical energy efficiently. Explore a new era of sustainable power with our

6 FAQs about [Motor energy storage device]

What is mechanical energy storage?

Mechanical energy storage can be added to many types of systems that use heat, water or air with compressors, turbines, and other machinery, providing an alternative to battery storage, and enabling clean power to be stored for days. Explore energy storage resources Simple physics meets advanced technology.

How do mechanical energy storage systems work?

Mechanical energy storage systems take advantage of kinetic or gravitational forces to store inputted energy. While the physics of mechanical systems are often quite simple (e.g. spin a flywheel or lift weights up a hill), the technologies that enable the efficient and effective use of these forces are particularly advanced.

How does a high-speed flywheel energy storage system work?

Most modern high-speed flywheel energy storage systems consist of a massive rotating cylinder (a rim attached to a shaft) that is supported on a stator – the stationary part of an electric generator – by magnetically levitated bearings. To maintain efficiency, the flywheel system is operated in a vacuum to reduce drag.

How does a motor work?

In a typical motor, a component called a rotor turns inside a stationary component called a stator. One of those components contains permanent magnets that have south and north poles. The other has wire coiled around it. Putting electricity through the coils creates magnetic fields that attract and repel the poles of the permanent magnets.

What is a self-bearing motor?

In a conventional brushed direct-current motor, the magnets are in the stator and the coils go around the rotor. The rotor is supported by a pair of mechanical bearings. But those bearings tend to wear out—especially when the rotor spins quickly. So about 20 years ago, researchers developed a “self-bearing motor.”

What are the advantages of Flywheel energy storage?

Some of the key advantages of flywheel energy storage are low maintenance, long life (some flywheels are capable of well over 100,000 full depth of discharge cycles and the newest configurations are capable of even more than that, greater than 175,000 full depth of discharge cycles), and negligible environmental impact.

More industry information

- Energy storage inverter temperature

- How much electricity does an 8 kilowatt solar panel generate

- Libya Gyumri Base Station Energy Storage System Manufacturer

- Croatian professional manufacturer of energy storage lithium batteries

- South African home inverters

- Latest requirements for wind solar and energy storage

- Tanzania wind power system battery

- Bhutan Outdoor Portable Power Company

- Uzbekistan solar panels

- Energy storage cabinet battery domestic market share

- Comoros Energy Storage Inverter

- Advantages and disadvantages of energy storage gel batteries

- Chile photovoltaic inverter distribution

- Which is the best energy storage cabinet for Peru s heavy industry

- Kenya energy storage power station subsidies 2025

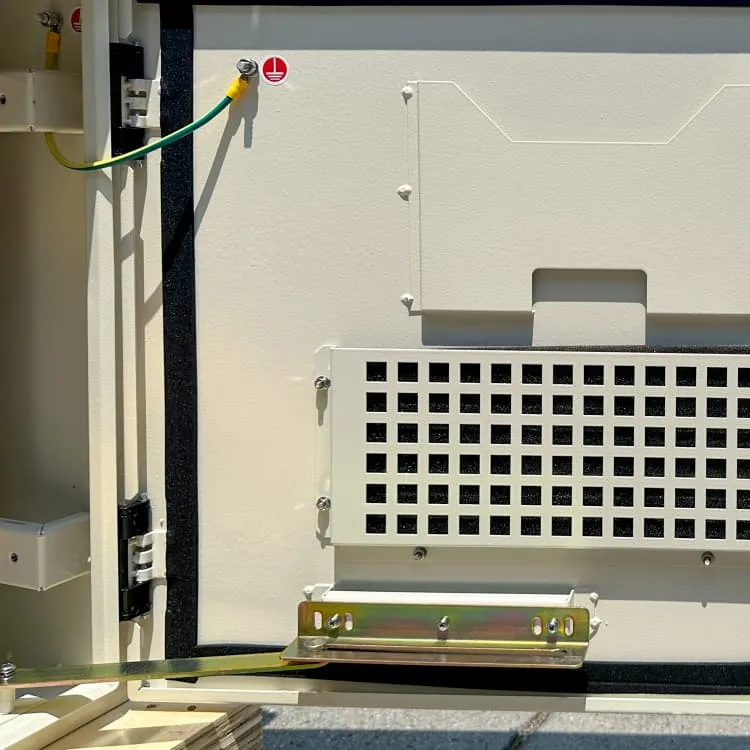

- Base station power equipment cabinet installation

- Huawei base station equipment power supply

- 5G communication base station wind and solar complementary construction government

- Ukrainian polycrystalline photovoltaic panel prices

- Estonia s requirements for wind power construction of communication base stations

- Energy storage cabinet anti-backflow

- 12 kWh energy storage power supply

- 75kw container power generation

- Belize develops outdoor power charging

- Ukrainian energy storage container manufacturer

- Cameroon BMS Battery Management Control System

- Sao Tome and Principe Power Plant Energy Storage Project