Power requirements for battery cabinet processing equipment

How to design an energy storage cabinet: integration and

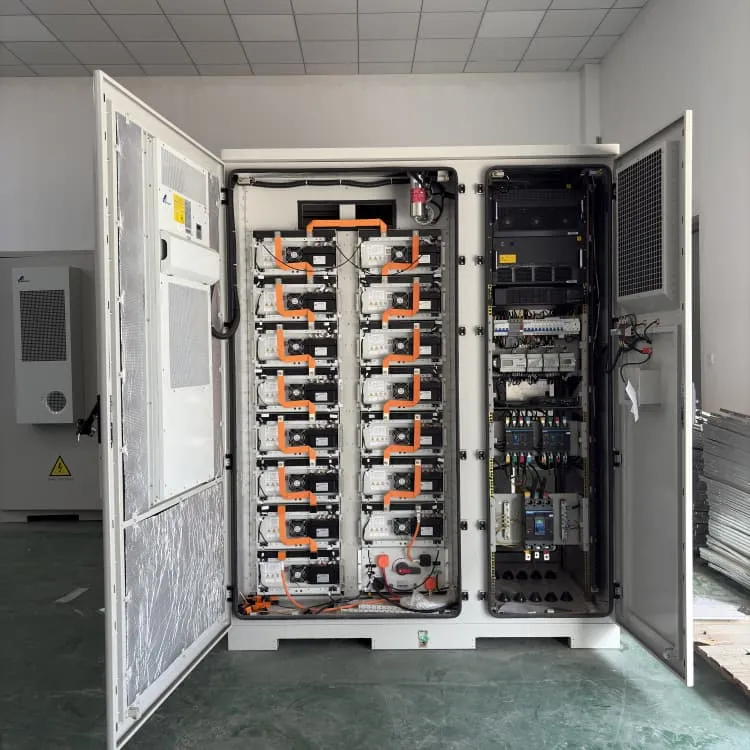

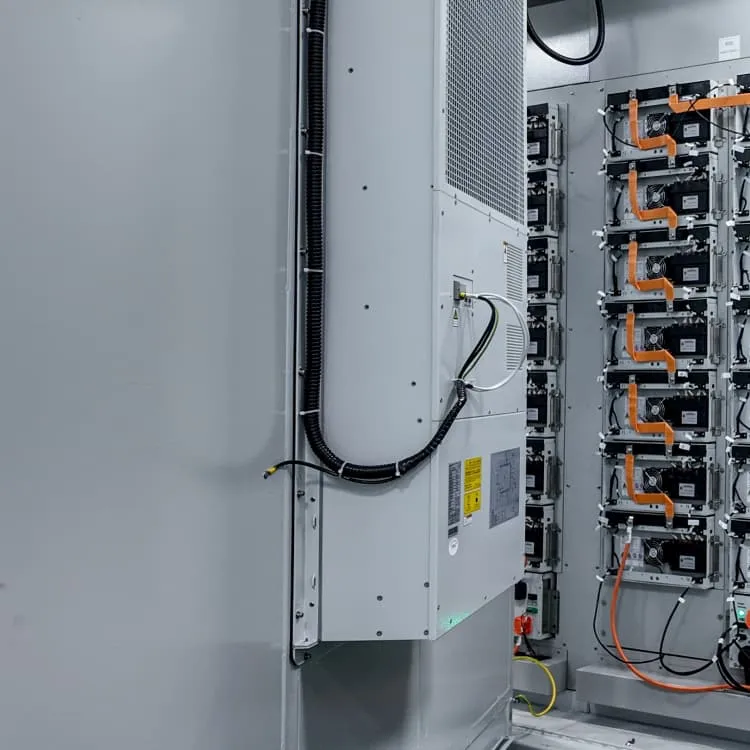

The power conversion system (PCS) is one of the key devices in the energy storage cabinet, responsible for converting the direct current (DC) stored in the battery into alternating

Accuracy requirements for battery aging cabinets in battery PACK

The accuracy of the aging cabinet is a key indicator in the production process of battery PACK, which directly affects the accuracy and reliability of battery performance testing.

Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards.

MTC''s Essential Guide to Battery Charging Rooms

MTC, a leader in battery handling solutions, offers comprehensive services to design and install all necessary equipment for a battery room, from battery stands to wash cabinets as well as

Accuracy requirements for battery aging cabinets in battery PACK

Power battery companies (such as CATL and BYD) usually require aging cabinet accuracy: Voltage ± 0.2% FS, current ± 0.3% FS, temperature ± 1 ℃, to meet the reliability

New UL Standard Published: UL 1487, Battery Containment

Learn about the first edition of UL 1487, the Standard for Battery Containment Enclosures, a binational standard for the United States and Canada published by UL Standards and

Standard Specification EPIC Series Battery Cabinet

For NEMA 3R, and when environmental options are provided, the battery cabinet will maintain a steady internal temperature of 77o F (+/- 3°F) through an external ambient temperature of

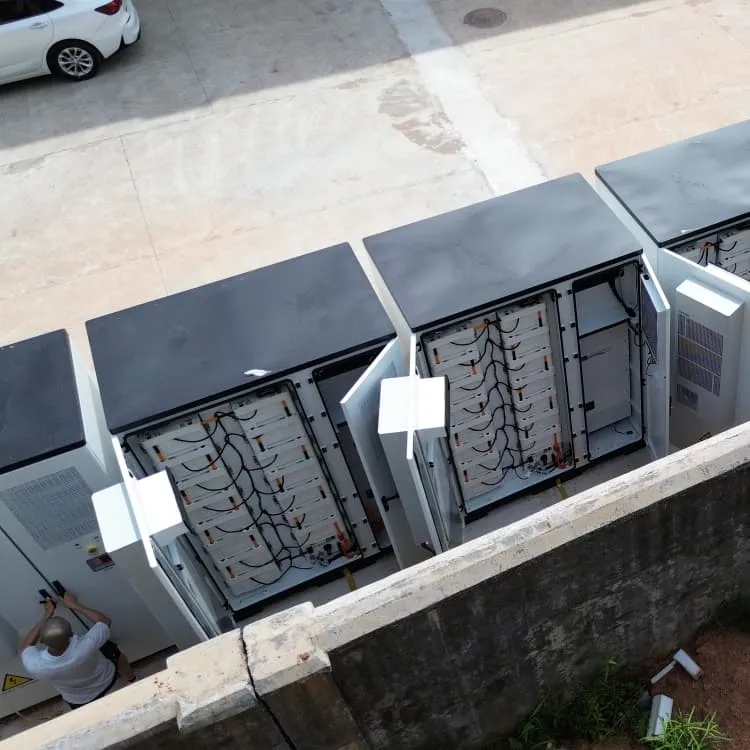

Utility-scale battery energy storage system (BESS)

Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and conversion – and

Choosing the Right Lithium Ion Battery Cabinet: A Complete Guide

The right lithium ion battery cabinet is a vital investment for any business using rechargeable power systems. It protects against fire, enhances compliance, and streamlines

Battery production equipment and services

Dürr offers equipment for every stage of the value chain – not only paving the way for the production of efficient, high-quality batteries and electric vehicles, but also supporting future

6 FAQs about [Power requirements for battery cabinet processing equipment]

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

How much power does a cabinet use?

When planning for power redundancy, each circuit (primary and redundant) must be sized to handle the total load of both in case one fails. We find that the cabinet’s equipment is pulling 1,872 watts (almost 1.9 kilowatts). Make sure to leave wiggle room for “power creep,” as all IT equipment consumes more power over time.

What are the requirements for a battery room ventilation system?

The ventilation system is determined such that the hydrogen concentration shall be limited to less than 1% of the total air volume of the battery room. Audible and visual alarm shall be installed outside the battery room entrance to annunciate a failure in ventilation for immediate action.

What should be included in a battery room?

Cabinets or racks shall be provided in the battery room for storing maintenance tools and safety equipment. These cabinets and racks shall be acid or alkaline resistant as applicable. Battery rooms shall be vented to the outside air by forced ventilation to prevent accumulation of hydrogen and to maintain design temperature.

Do you need documentation before entering a battery room?

It is a requirement to have all the documentation in place prior to authorized personnel entering a battery room to perform a specific work task on a battery system under normal operating conditions. However, it is likely the employee will need to enter the battery room to deal with a battery system that is not operating normally.

More industry information

- Botswana dedicated solar photovoltaic panels

- Huawei Benin flexible photovoltaic panels

- Huawei single-phase industrial off-grid inverter

- Thin-film photovoltaic module design solution

- How much does it cost to replace the lithium battery station cabinet in the UAE

- Ukrainian outdoor mobile power box price

- What is the price of environmentally friendly inverter in Morocco

- Brand solar power supply system

- Nicaragua power grid 30kw distribution energy storage

- 25W solar photovoltaic panel price

- Palau Tian New Energy Power Station Energy Storage

- What is the price of the Burkina Faso industrial and commercial energy storage cabinet factory

- 25kw power inverter

- Price inquiry for outdoor communication battery cabinet in Ghana

- How to charge the energy storage cabinet ESS power base station

- 1kW wind-solar hybrid power generation system combination

- Do flow batteries for communication base stations in the Netherlands need to be approved for construction

- Is a 100w photovoltaic panel enough for home use

- Equatorial Guinea Communications BESS Power Station Company

- Latest requirements for photovoltaic inverters in Uruguay

- Zambia Mobile Energy Storage Site Wind Power Planning

- Price of 1 square photovoltaic panel

- Outdoor power supply with solar panel

- Inverter connected to DC string

- What is the capacity of a 12v 500w inverter

- How many watts are 12 6V solar panels

- Integrated Energy Site Layout Planning