Pack battery equipotential

Equipotential bonding in the (ev) high voltage system:

Since both vehicle ground, high-voltage battery body and power electronics are conductively connected to each other via the equipotential bonding, a short-circuit current will flow via the

Crash Safety of High-Voltage Powertrain based Electric

metal frame and chassis to contact the battery electrode or the joints between battery packs and power electronic devices (precautions lose efficacy). This issue arises from the RESS system

Connections Between Temperature Consistency in Battery Pack

To prevent battery thermal runaway for electric vehicles (EVs), it is necessary to figure out and apply the connections between temperature consistency in battery pack (TCBP)

Resolving Kirchhoff''s Laws for Parallel Li-Ion Battery Pack State

To illustrate the potential of the proposed model for pack-level control and estimation, a method to bound the error of a state-estimator is introduced and the modeling

The Fundamentals of Battery/Module Pack Test

Before we discuss how to select the right battery test equipment for a given application, certain key challenges and fundamental concepts of battery testing will be reviewed. This application

ASE Electrified Propulsion Vehicles (xEV) High-Voltage

<B1> Electrically Safe Work Condition An electrically safe work condition is a state in which a high-voltage electrical conductor(s) or circuit part(s), excluding inside the high-voltage battery

Towards impedance‐based temperature estimation for Li‐ion battery packs

The (average) internal battery temperature can be inferred from the battery impedance using Electrochemical Impedance Spectroscopy. Since the existing literature

Electric components in automotive battery systems above 800 V

Abstract The electric vehicles currently available have nominal system voltages of 400 V, which results in load currents up to a few 100 A. When carrying such currents, electric components,

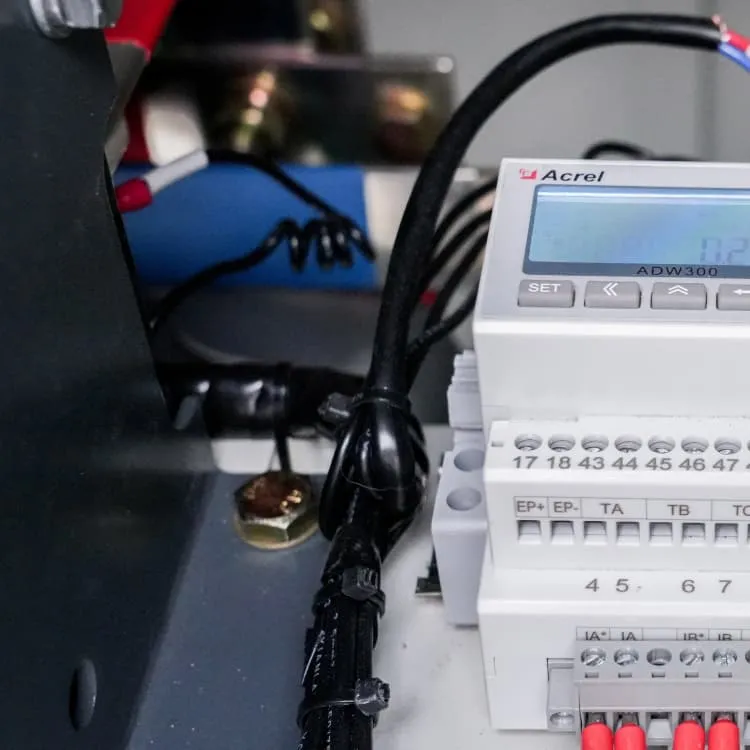

Lithium-ion Battery Pack End-Of-Line Testing System for EV Battery

The EV battery pack End-Of-Line test system is specially designed for high-power lithium-ion battery packs. It is mainly used to test and verify the failures and safety issues that may occur

Internal resistance matching for parallel-connected lithium-ion

When assembling lithium-ion cells into functional battery packs, it is common to connect multiple cells in parallel. Here we present experimental and modeling results

Co-estimation of state-of-charge and capacity for series

Battery pack configuration develops toward the series connection due to the high energy density of the individual battery cell and lower management difficulty. Therefore, the

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs and energy storage.

Battery Test Manual For Electric Vehicles

As in previous battery and capacitor test manuals, this version of the manual defines testing methods for full-size battery systems, along with provisions for scaling these tests for modules,

6 FAQs about [Pack battery equipotential]

What is battery module and Pack testing?

Battery module and pack testing involves very little testing of the internal chemical reactions of the individual cells. Module and pack tests typically evaluate the overall battery performance, safety, battery management systems (BMS), cooling systems, and internal heating characteristics.

What is lithium-ion battery pack EOL testing system?

Product description: The lithium-ion battery pack EOL testing system is used for EV battery End-Of-Line test, it is not a specific standard test equipment, but customized by customer on EOL test requirements. Product description: The EV battery pack End-Of-Line test system is specially designed for high-power lithium-ion battery packs.

What is EV battery pack end-of-line test system?

The EV battery pack End-Of-Line test system is specially designed for high-power lithium-ion battery packs. It is mainly used to test and verify the failures and safety issues that may occur during the entire EV battery pack assembly process to ensure that the EV batteries are safe and reliable. Scope of application:

What is a battery pack?

A battery pack contains any number of battery modules along with additional connectors, electronics, or packaging. The above distinction is important as battery cells are treated as individual components whereas battery modules and packs are treated as an assembly (reference Figure 3).

What is equipotential bonding?

In any (ev ) high voltage training course, measuring equipotential bonding is a key exercise. Equipotential bonding within an HV (ev) component as well as equipotential bonding between any two high-voltage components in an electric vehicle. Specifically, between the housings, as the bodies of the respective high-voltage components.

What is asutpp equipotential bonding?

Meaning, Requirements, Examples – Asutpp Equipotential bonding (EPB) is a set of electric connections intended to achieve equipotentiality between conductive parts [Source: IEC 60050-195-2021]. The British Standard BS 7671 defines the term “equipotential bonding” as follows:

More industry information

- Jordan s industrial and commercial solar power generation system

- Azerbaijan solar energy storage module prices

- Energy storage cabinet low voltage cabinet

- Base Station Power Supply Considerations

- Personal solar rooftop per kilowatt

- Luxembourg Container Energy Storage Company

- How many watts of battery are needed for a 100w solar panel

- Base station battery algorithm image

- Black Mountain Outdoor Energy Storage Power Communication BESS Company

- Home energy storage to AC power

- Malta Outdoor Power Rescue

- Introduction to Flow Batteries

- How much does the Austrian station-type energy storage system cost

- Which is better for home use solar power generation or power generation

- Yemeni battery energy storage manufacturer

- Will there be solar power generation for home use in 2025

- Philippines Outdoor Battery Cabinet BESS

- Uganda outdoor battery cabinet bms battery

- 1400w home solar power system

- Principles of wind-solar complementary construction of communication base stations

- High voltage industrial frequency sine wave inverter

- Inverter and three strings of lithium batteries

- Energy Storage Container Site Communication Introduction

- Lead-carbon battery energy storage time

- Where is energy storage power needed

- $30 000 solar power system

- Moldova Independent Energy Storage Power Station